Performance. Resilience. Intelligence.

Transform your production chain with Inspectorio's AI-powered supply chain management platform.

Leading Companies Choose Inspectorio

Turn Your Supply Chain Into a Competitive Advantage

Use innovative technologies like AI to unlock advanced analysis and insights of your connected supply chain data, enabling optimal decision making on issues that are critical to your success.

Put Future Technologies Into Action

Use innovative technologies like AI to unlock advanced analysis and insights of your connected supply chain data, enabling optimal decision making on issues that are critical to your success.

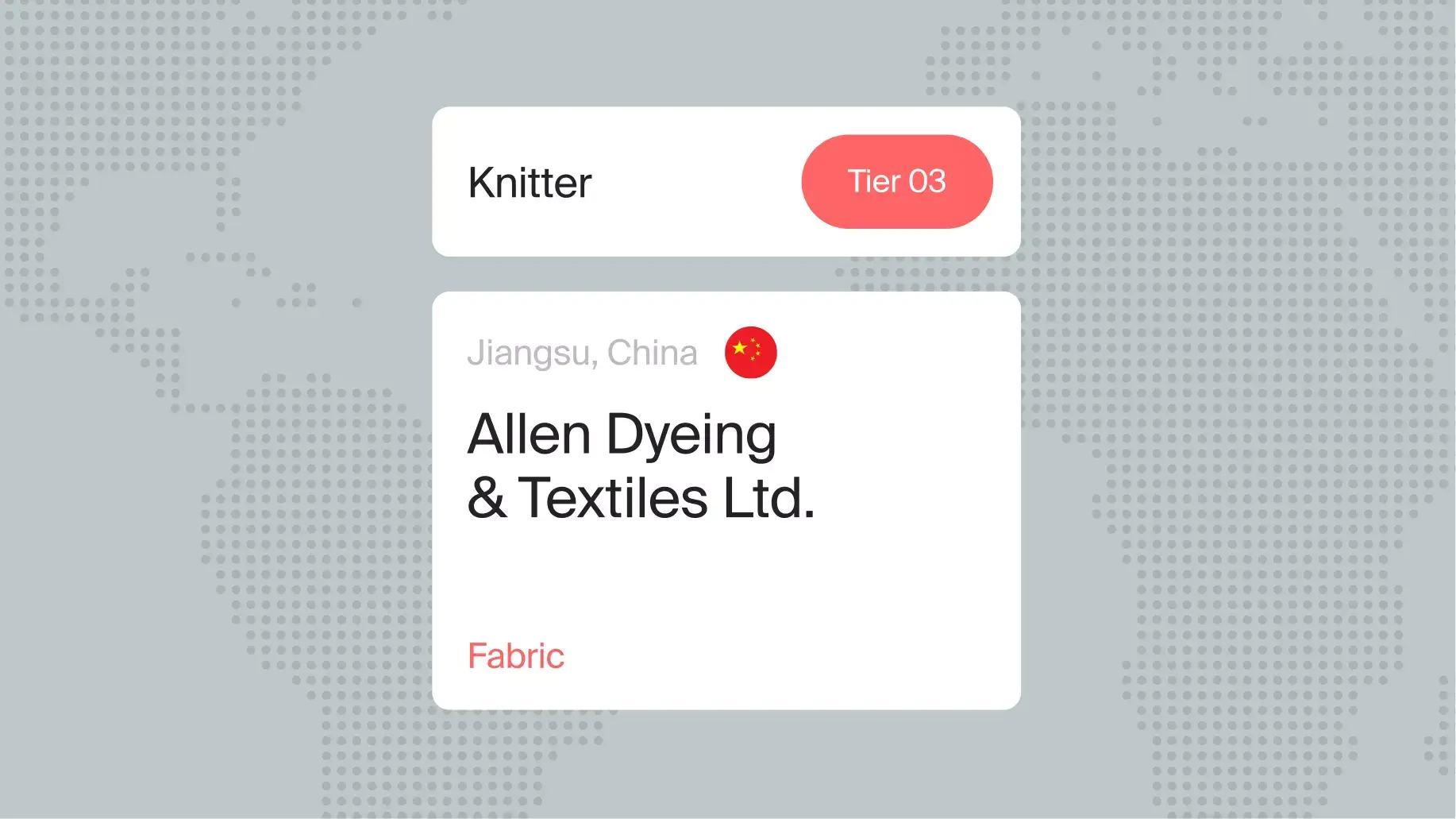

The Inspectorio Platform digitizes and connects your supply chain management processes within a single tool to break down silos across your organization, enable intelligent analysis of your entire ecosystem, and allow for scalability of your operations.

Connect Your Supply Chain Management Operations

The Inspectorio Platform digitizes and connects your supply chain management processes within a single tool to break down silos across your organization, enable intelligent analysis of your entire ecosystem, and allow for scalability of your operations.

Our platform empowers your team to achieve strategic sustainability and sourcing goals in the supply chain through data-driven insights, increased transparency, and operational efficiencies that lead to increases in essential supplier engagement.

Maximize Your Global Impact

Our platform empowers your team to achieve strategic sustainability and sourcing goals in the supply chain through data-driven insights, increased transparency, and operational efficiencies that lead to increases in essential supplier engagement.

Make decisions faster to reduce your production chain risks with advanced analytics and supply chain network management functionality in our intelligent platform.

Reduce Your Risks

Make decisions faster to reduce your production chain risks with advanced analytics and supply chain network management functionality in our intelligent platform.

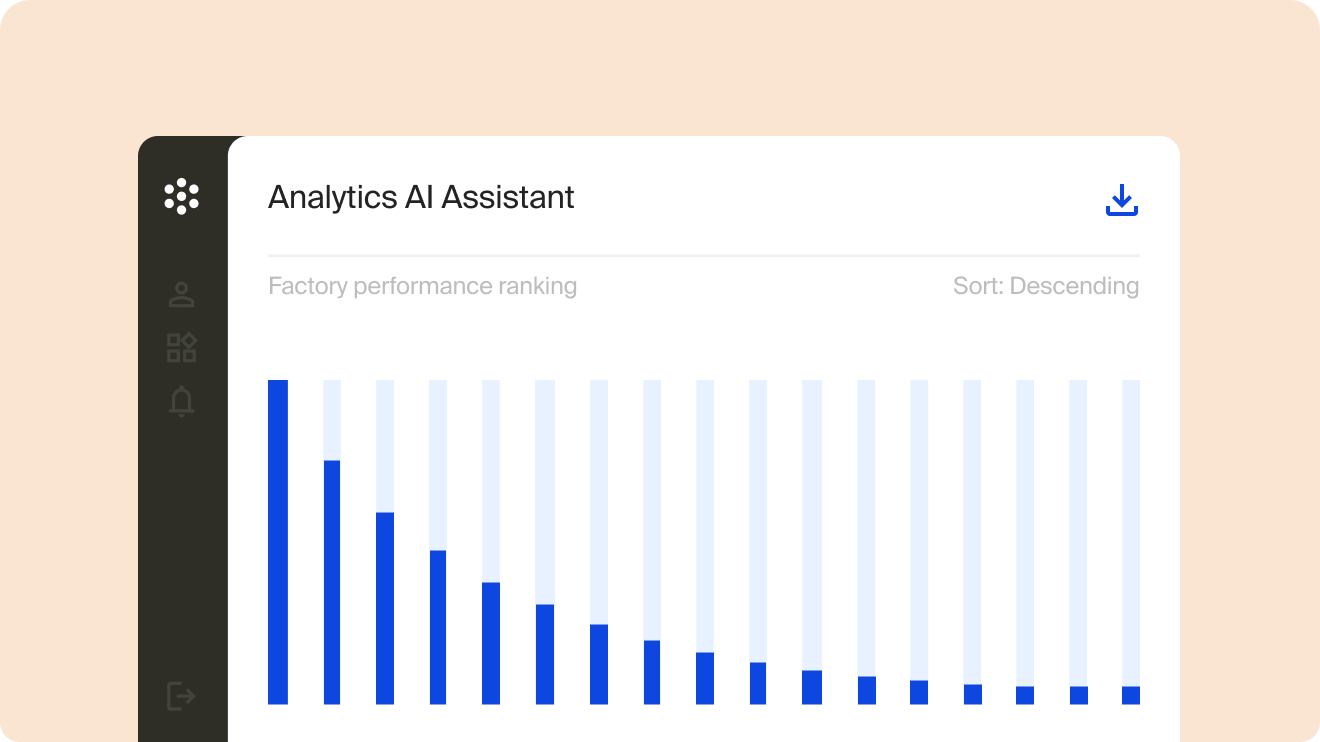

Gain access to advanced analytics that pull data from across the entirety of your supply chain, enabling dynamic risk assessments and intelligent recommendations to improve ecosystem performance.

Drive Better Performance with Advanced Analytics

Gain access to advanced analytics that pull data from across the entirety of your supply chain, enabling dynamic risk assessments and intelligent recommendations to improve ecosystem performance.

Inspectorio’s Intelligent Supply Chain Management Platform

Trusted by 12,000+ brands, retailers and suppliers across the globe

G2

4.9 STARSCapterra

4.7 STARSGetApp

4.6 STARSSolutions For Your Industry

Apparel & Footwear

Food & Beverage

Home & Furniture

Multi-Category Retail

Outdoor & Sports

High-quality goods go beyond style and stitching to include responsibly sourced and sustainable materials. Inspectorio enables top apparel and footwear companies to measure, action, and improve performance across all these areas, building brand equity and meeting consumer expectations to ultimately drive revenue.

Learn more

Learn more

Learn More About Inspectorio

The time is now for a transparent and resilient supply chain.

Book a demo

Book a demo

Request a Demo

Become a partner

Subscribe to receive our newsletter

Sign Up to the Webinar

Contact Us