Garment Maker Interloop Revamps EHS Initiatives with Inspectorio Responsible Sourcing & Compliance

The case studies mentioned herein were conducted using our earlier individual solutions: Inspectorio Sight (now Quality Risk Management), Inspectorio Rise (now Responsible Sourcing & Compliance), and Inspectorio Tracking (now Production Management). Inspectorio transitioned to a unified platform approach, enhancing and interconnecting these solutions under the Inspectorio Platform to better serve our customers. Click here to learn more about the Inspectorio Platform.

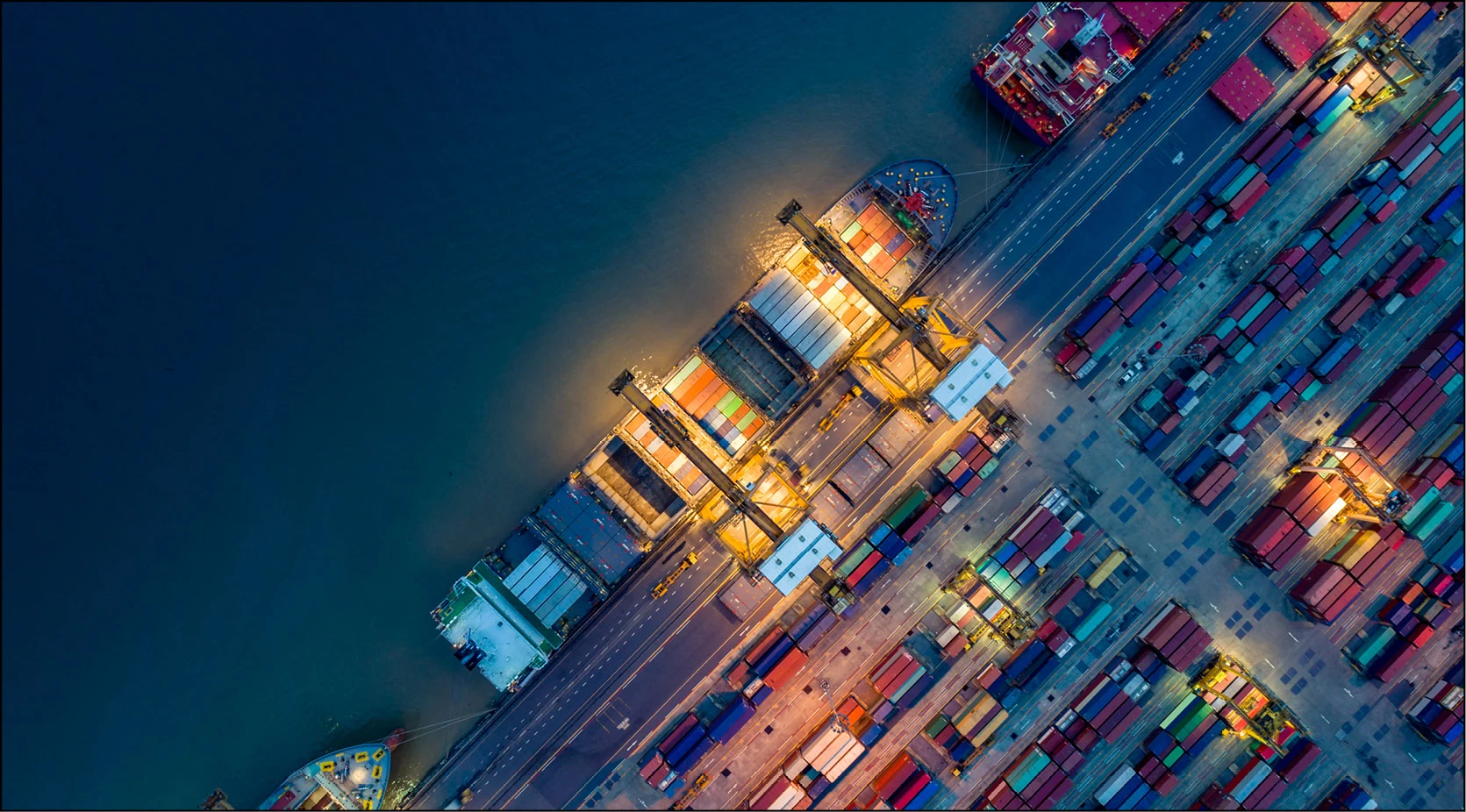

When it comes to complexity, the modern world continues to surpass all expectations. An increasingly interconnected global supply chain is subject to the whims of geopolitics, pandemics, trade agreements, and ever-shifting consumer concerns. Proactive supply chain executives must weigh the costs and benefits of diversification, near-shoring, and other risk management tactics, all while keeping an eye on developments that can change the face of commerce overnight.

But as Pakistan-based garment manufacturer Interloop has found, the most consequential step toward resilience came simply from digitizing their supply chain. Inspectorio Responsible Sourcing & Compliance, an award-winning and revolutionary factory compliance monitoring platform, has not only allowed Interloop to maintain hi-res visibility over their supply chain during the COVID-19 pandemic, but it has also transformed business practices in their Environment, Health, and Safety (EHS) initiatives.

Responsible Sourcing & Compliance empowers businesses with radical transparency, allowing them to monitor compliance with environmental, social, sustainability, and health and safety initiatives in real time.

Factories can leverage Responsible Sourcing & Compliance to hold themselves accountable and reduce the need for in-person compliance audits. By building this foundation of accountability, leading global suppliers like Interloop are using Responsible Sourcing & Compliance to transition away from conventional business relationships — which have relied on policing and penalizing — to relationships based on mutual trust and empowerment.

Who is Interloop?

Interloop is a vertically integrated multi-category full-family clothing company that produces textiles and apparel for many of the world’s biggest brands and retailers, including adidas, Nike, Target, and others. Having started in 1992 with just ten knitting machines, today they occupy a $300 million acre of the market with a company spanning three continents.

Like many in the manufacturing sector, Interloop relies on a widespread network of factories to deliver quality products while continuously improving production practices.

When the pandemic struck in 2020, the company quickly discovered the need for better implementation and oversight of standard operating procedures. Inspectorio Responsible Sourcing & Compliance provided the solution — soon after onboarding, Interloop had full visibility over their entire production ecosystem.

How has Inspectorio Responsible Sourcing & Compliance helped Interloop?

Inspectorio Responsible Sourcing & Compliance leverages intuitive, minimalistic hierarchical design to remove the barriers between supply chain executives and their factories. Using collaborative tools like interactive maps, assessment completion tracking, highly filterable and searchable data, corrective and preventive action plans (CAPAs), and analytics that provide actionable insights, Interloop has been able to implement far-reaching safety measures in a faster timeframe than would have previously been possible.

According to Interloop, “Inspectorio Responsible Sourcing & Compliance is a valuable platform being used by our EHS teams across our manufacturing facilities,” allowing them to “evaluate and assess the implementation and results of the standard operating procedures.”

This novel capability quickly allowed the company to protect their workers and supply chain partners from contamination in the COVID-19 pandemic. By standardizing the evaluation process across all manufacturing facilities, Interloop says that Responsible Sourcing & Compliance ensures “that the safety precautions are in place at all plants/facilities across our supply chain, with greater focus on reducing, reporting, and addressing any divergence.”

With health and safety regulations in place and with real-time visibility over continued compliance, the other benefits of the Responsible Sourcing & Compliance platform came into play. Formerly time-consuming manual processes became trivial, including expensive in-person audits being largely replaced by factory self-assessments.

“Since the commencement of this program at Interloop, we have undergone three months of self-assessment cycles across all our manufacturing plants,” Interloop says.

The benefits of self-assessments extend beyond saving time. This capability promotes active collaboration between brands and retailers, vendors, and factories across the spectrum of facility-level audits. Audit fatigue, which remains a leading problem within the compliance industry, stems from vendors having to perform repetitive audits for different clients — all for the same results.

According to Interloop, these self-assessments have generated “reports that have helped…ensure that the safety guidelines are being followed 100%” across their ecosystem.

The pandemic also proved Rise’s ability to facilitate guideline implementation through groundbreaking visibility and transparency. For Interloop, this has not only meant ensuring “safe working conditions at our facilities by prevention and control during the pandemic,” but also the ability to upload protocols and have them “be followed and implemented across all our plants…by monitoring the procedures and activities, and consequently, taking corrective actions for continuous improvement in real-time.”

As the company continues to grow on the other side of the pandemic, swift and transparent guideline implementation will be crucial to remaining agile and resilient against future disruptions.

Interloop was also able to onboard Inspectorio Responsible Sourcing & Compliance and homogenize it across their multinational supply chain in very little time. Thanks to best-in-class UI and UX, as well as E-learning resources that let new users become proficient in under an hour, the company quickly integrated Responsible Sourcing & Compliance into the core of their practices.

This immediately had a profound impact on the company’s operations, “transforming our business practices to safeguard the health and safety of our people across all plants.”

Moving forward, Interloop will continue to use Responsible Sourcing & Compliance to drive continuous improvements and manage their operational risk: “The Responsible Sourcing & Compliance platform provides a transparent process that helps reduce the risk of errors or manipulations,” says Interloop, “which in turn creates smooth and efficient connectivity across all operational networks.”

This will nurture a new foundation for their “corporate EHS team to oversee implementation” of new initiatives, as well as mitigate “any deviations from defined standard guidelines through generation of corrective and preventive action reports. Thus it helps plug any gaps identified during assessments.”

Benefits of the Responsible Sourcing & Compliance platform

Responsible Sourcing & Compliance is uniquely positioned to digitally transform companies. It lets organizations implement and monitor guidelines, leverage real-time automatic reporting and analytics, automatically issue corrective actions and interactive training, plan with the help of high-resolution data, and more. The following are a sampling of its benefits:

Standardization across all manufacturing facilities

Digital transformation is no longer a difficult or resource-intensive process. Thanks to rapid implementation and dedicated support, Inspectorio Responsible Sourcing & Compliance allows companies to onboard a consistent platform across their supply chain in very little time.

Improved efficiency

Get rid of manual processes entirely thanks to a network-based platform, with every piece of data catalogued and incorporated into automatic, robust analytics produced with machine learning. Instead of requiring a dedicated team to interpret stacks of spreadsheets, Responsible Sourcing & Compliance provides comprehensive data analytics in seconds from anywhere in the world. This translates to data-driven insights that are free of subjectivity, allowing for stronger decision making.

Visibility and transparency

Perhaps the single most important aspect of the Inspectorio solution is its real-time visibility and transparency. Every corner of a production ecosystem is reviewable in a single centralized location. Inspectorio Responsible Sourcing & Compliance allows organizations to integrate data from third-party standards into a template, collect and verify self-assessment data, monitor continuous improvement initiatives, and more for all business partners and facilities in their network.

Continuous improvements

Today’s companies rely on overseas sourcing facilities to build their products. Yet now more than ever, they must be able to drive continuous improvement among their supply chain partners without letting distance diminish their communication. With Inspectorio Responsible Sourcing & Compliance, brands, retailers, and vendors can instantly disseminate new guidelines to every single stakeholder in the system, which include automatically generated CAPAs and online training programs.

Move your supply chain forward with Responsible Sourcing & Compliance

Inspectorio Responsible Sourcing & Compliance has been a vital resource for companies throughout the pandemic. Yet the very same capabilities that have made it a lifesaver during crisis make it a transformative force as we begin to approach the new post-COVID normal.

By helping companies improve environmental, sustainability, and social conditions in their factories, implement new health and safety guidelines, and monitor all of it in real-time, Responsible Sourcing & Compliance creates visibility and collaboration in a sector that has, until now, never been conducive to either.