5 Steps to Building an Effective Due Diligence Protocol in Your Supply Chain

The fashion industry is at an inflection point. Both public scrutiny and regulations, growing rapidly despite having already reached record levels, have made due diligence a non-negotiable part of brands’ and retailers’ supply chain operations.

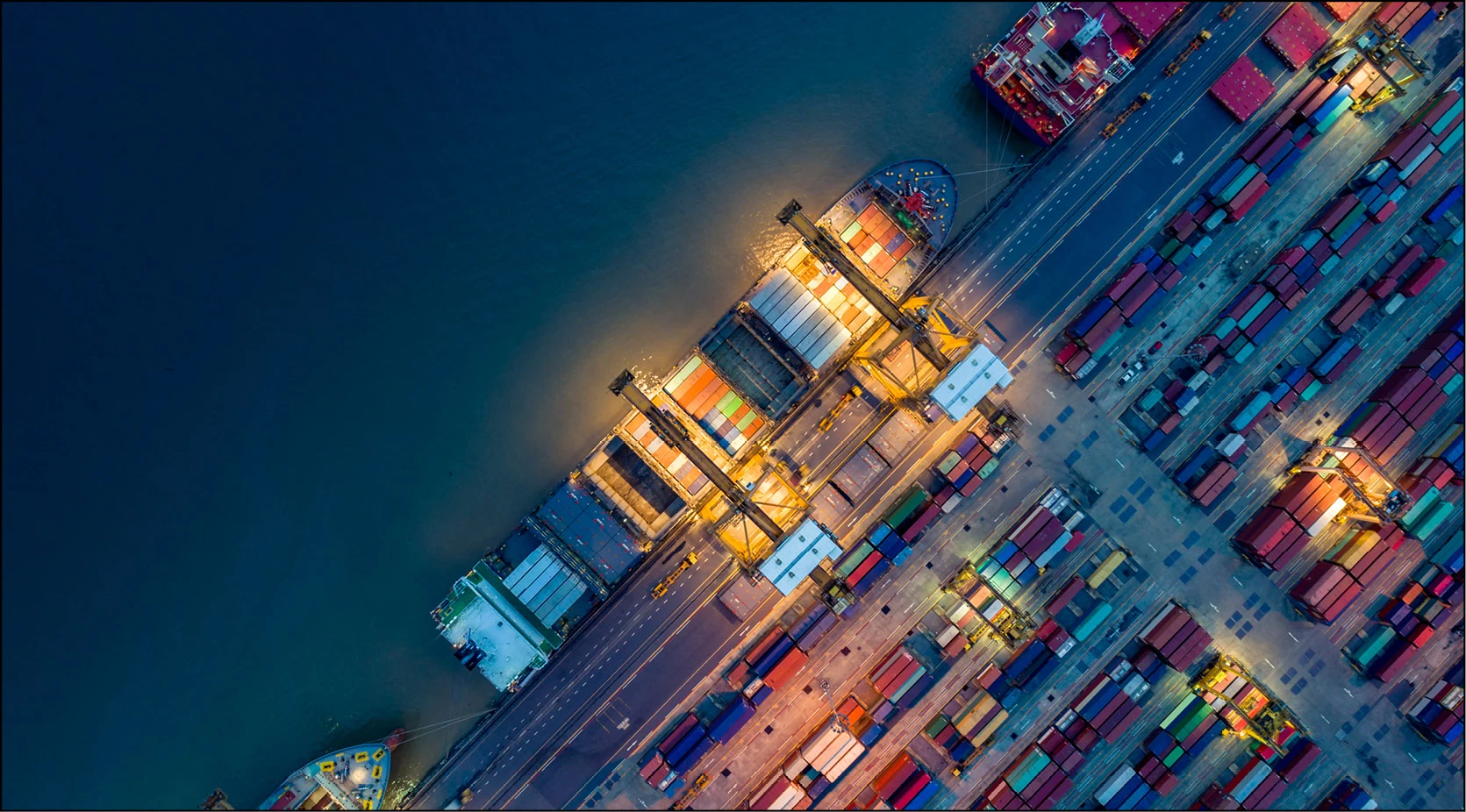

Due diligence refers to a company’s process for preventing human rights and environmental harm in the production of their merchandise. This would not be an issue if companies only sourced from a handful of suppliers, but globalized supply chains today span dozens of countries and far more individual suppliers. Using conventional supply chain management to conduct due diligence over large production chains is almost guaranteed to fail. Not only is it impossible to achieve real-time visibility, but there is also the issue of uncovering hidden suppliers behind your tier 1 partners.

To build meaningful due diligence in your supply chain — a due diligence protocol that actively prevents harms and controversies based on real-time data and autonomous processing — you need to embrace new technologies and know how to roll them out in your supply chain.

The current state of the industry

Regulations are on the rise, as are their scope and enforceability.

Examples of regulatory packages include the EU’s proposal for a Directive on Corporate Sustainability Due Diligence and the UK Modern Slavery Act, which mandate that companies exercise rugged and provable due diligence against forced labor in their supply chains.

According to the ISS ESG Norm-Based Research team, textiles and apparel top the list of industries most likely to be involved in human and labor rights and environmental controversies. Unfortunately, only 34% of companies examine how their value chains impact biodiversity, and only 17% examine upstream and downstream impacts.

Over 15 countries are either proposing or implementing environmental impacts and human rights regulations. Such laws require companies and their investors to identify, mitigate, rectify, and disclose adverse human rights impacts in their supply chains. Also at play is single-issue regulation on issues like:

- Modern slavery

- Indigenous rights

- Deforestation

- Child labor

However, single-issue legislation is declining in favor of stricter, broader-scope regulation. For instance, Norway and Germany passed due diligence regulations in 2022 and 2023 that align closely with the UN’s broader conventions on the cultural, civil, workplace, and political human rights.

Regulation enforcement is also strengthening. Moving from the carrot to the stick is central to new regulation. The EU’s directive, for example, proposes having member states enforce new regulations, would allow victims to sue companies for damages, and expands the definition of directors’ duties to include addressing sustainability issues.

Public scrutiny is mounting even faster, with companies facing devastating and often fatal losses when scandals emerge.

5 critical steps to implement due diligence in a modern supply chain

The following five steps detail how to build a due diligence protocol that will move the needle on your supply chain’s human rights and environmental impacts:

Step 1: Integrate responsible processes into your policy and management

The Organisation for Economic Co-operation and Development (OECD) guidelines recommend that companies “make policy commitments on disclosure and human rights” to build due diligence.

Understand that subcontracting increases the risk

As you begin to plan how to act on your policy commitments, you will need to map out your entire supply chain.

Tier 1 suppliers are relatively straightforward; however, subcontracting to tier 2 and 3 parties is common throughout the garment and footwear value chain. This outsourcing tends to “decrease transparency in the supply chain” and “increase the risk of human rights and labor abuses and environmental impacts,” writes OECD.

Set clear expectations with partners 🎯

- Agree on whether subcontracting is permitted

- If subcontracting is permitted- Find out who those subcontractors are

– Establish requirementson their selection and transparency. For example, subcontractors should pass the same prequalification criteria as tier 1 suppliers

– Collaborate to develop Corrective And Preventive Actions (CAPAs)for subcontractors

– Encourage suppliers to monitor their subcontractors actively

Simplify complexity

Mapping your supply chain is time-consuming and made more complex by the sheer number of partners in your production ecosystem. A digital network platform like Inspectorio Rise makes it possible to keep track of all tiers of partners in your network and view them and their status on a real-time map. This lets you monitor variables like risk and implementation at a glance, so you know where to focus your attention.

Inspectorio also keeps all communication on-platform, creating a single source for data, analytics, and messaging between stakeholders.

Step 2: Identify current areas of potential risk

Conduct a comprehensive search for risks of harm in your supply chain. Start with known risks in the industry and the factors contributing to those risks, and analyze the likelihood of those risks occurring based on factors like:

- Product lines: Products may hold greater risk due to the materials used to make them, such as cotton (greater risk for toxic insecticide use) and polyester (greenhouse gas-intensive).

- Country of manufacture: Factors like governance, industry characteristics, and socio-economic realities make certain countries riskier than others to source from. For example, countries with more migrant labor tend to have higher rates of forced and child labor, sexual harassment, and illegally low wages.

- Business model: A high number of product lines and frequent changes in product lineup increase the risk of harm due to the high variance in materials, shorter lead times, and a higher carbon footprint.

- Sourcing practices: More suppliers means a greater risk of harm, as does the practice of entering short-term relationships with suppliers. Likewise, sourcing indirectly from subcontractors dramatically increases risk.

Move downstream to upstream, big to small

As you perform this self-assessment, track risks across the entire length of the value chain, from raw materials to store shelves. For complex products, start big and work your way down: for a leather jacket, for example, start with the leather and then work down to things like zippers and studs.

Keep the lines of communication open

Transparency and collaboration are essential during this phase. Reach out to potentially affected stakeholders like trade unions, workers, and other employees as you identify harms.

Use site assessments and choke points as needed

When you identify suppliers with higher levels of risk, assess them at the facility level. This can be difficult for those above tier 2 (e.g., raw materials); try to leverage choke points in this situation. These are small channels that the majority of goods pass through, such as a single supplier that holds strong control or visibility over upstream suppliers.

Collaborate with your competitors

A keyword through all this is collaboration. OECD recommends “enterprises sourcing from the same sourcing country and production clusters within countries” to identify risks.

Until recently, the idea of competitors collaborating to achieve a common, mutual benefit was optimistic at best. Now, thanks to network platforms like Inspectorio, all users benefit from each other’s data in a secure, anonymized way. This is known as pre-competitive collaboration, and it represents one of the most profound revolutions in the sphere of due diligence.

Step 3: Mitigate harm in your supply chain

The immediate goal is to stop harmful practices in their tracks; the next goal is to prevent them from happening again.

Corrective action plans

Stopping harmful practices requires a corrective action plan (not to be confused with CAPAs, which are smaller in scope), which should clearly detail the appropriate responsive actions and their timelines. These plans tend to include the following components:

- Policy

- Training

- Facility upgrades

- Management system upgrades

- Workers’ rights

If there are too many issues to tackle at once, take a staged approach by addressing the most pressing issues first.

Remediate harm done

If you determine your supply chain has contributed to environmental or human harm, find a way to help remediate it. Remediation is often called the “forgotten pillar” of the UN Guiding Principles on Business & Human Rights, but it is a critical part of meaningful due diligence.

Analyze what factors are associated with harm

Certain factors, including orders placed or changed last minute, may be associated with increased harm. Identify these factors and set up systems to automatically track them.

Take a preventive approach

An ounce of prevention is worth a pound of cure, and nowhere is this more true than when it comes to protecting the environment and human lives at scale.

Platforms like Inspectorio Rise give you red flag warnings when AI-powered analytics detect risk for harm. Furthermore, the platform automatically books social compliance, sustainability, and environmental audits triggered by elevated risk levels, meaning your system will run preventively and autonomously.

Step 4: Track implementation

With your corrective action plan in place across your supply chain, you need to be able to monitor and validate progress on your due diligence initiatives. This is to verify that your supply chain partners are implementing measures on time and that those measures are effective.

Track qualitative and quantitative indicators to measure progress, communicating with auditors in real time when necessary. When a measure isn’t working, try to understand whether another measure is needed, whether the existing measure simply needs more time to take root, or whether the situation needs more resources.

Inspectorio Rise is the most advanced solution for booking compliance audits and monitoring them as they happen. All data points immediately enter the cloud and are stored with industry-leading security, giving you (and our autonomous analytics) access to all historical data as well as incoming information. This helps you measure progress against benchmarks and respond when help is needed.

Step 5: Communicate your progress

You need to publicly communicate your due diligence process and progress, including the various tools you’ve put in place to mitigate harm. Include the following information:

- Your due diligence policy, management systems, and methods for incorporating them into day-to-day supply chain activities

- The largest risks you identified in your operations and supply chain

- How you are addressing those risks (and potentially why you are addressing some before others

- The effectiveness of your measures

- Remediation of harms caused by your supply chain, including any resolved legal cases

Consumers, regulators, and investors today will demand to see proof of all of this. Inspectorio Rise makes that part straightforward — any data you present from the platform is trustworthy and verifiable, and you can make it available to any stakeholders you choose. Plus, Rise fosters continuous improvement across your supply chain, allowing you to set progressively more ambitious goals and set yourself apart in a market that values integrity.

Lead the charge with Inspectorio Rise

Due diligence is a make-or-break capability — don’t fall short with ill-equipped conventional methods when purpose-built technology is available. Inspectorio Rise brings all compliance operations under one roof:

- Internal audits

- Social compliance audits

- Sustainability audits

- Environmental audits

- Automated reports and CAPA

- In-platform communication

- Corrective and preventive action

- Data analytics

Read what some of the world’s leading brands, retailers, vendors, and suppliers say about Inspectorio Rise.